How To Clean Cast Iron Cylinder Heads

Put your gloves on to protect your hands from the chemicals used to clean the cylinder heads.

How to clean cast iron cylinder heads. Fill the second tub with warm water. Put the cylinder head in a large tub or container so that you can work on it. It will start to rust right away. Removing rust from cast iron heads and blocks usually requires a mild acid such as citric acid or phosphoric acid. Th ey will need to be cleaned using an abrasive blaster wire wheel brushes or taken to a shop to be hot tanked.

Ultrasonic cleaning can also dislodge iron oxide from the surface of castings. After you begin to feel comfortable using your die grinder and abrasive rolls completely clean your good engine heads. Cleaning the cylinder heads can be a dirty process and can be quite time consuming. You may want to do the following step outdoors or in a room with a drain. If you are working on aluminum heads remember that aluminum will abrade much faster than cast iron.

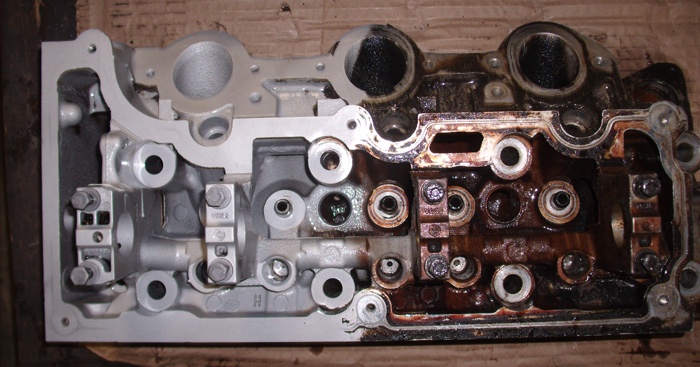

After you scrub your cylinder heads fill the second tub up with warm water. Make sure the tub is tall enough to allow the cylinder head to be completely submerged in water then fill it with enough water to completely cover the head. Baking soda has proved to be an effective cleaning media on cast iron and aluminum and can be used dry or mixed with water to create a cleaning slurry. The heads shown in this story are cast iron heads off of restoration projects not a race car but we used these to show just how bad heads can be corroded if this cleaning process is not. However when a water based cleaning process is used some type of corrosion inhibitor should always be added to the solution to prevent rust from reappearing after the parts have been cleaned.